ABOUT US

ABOUT US

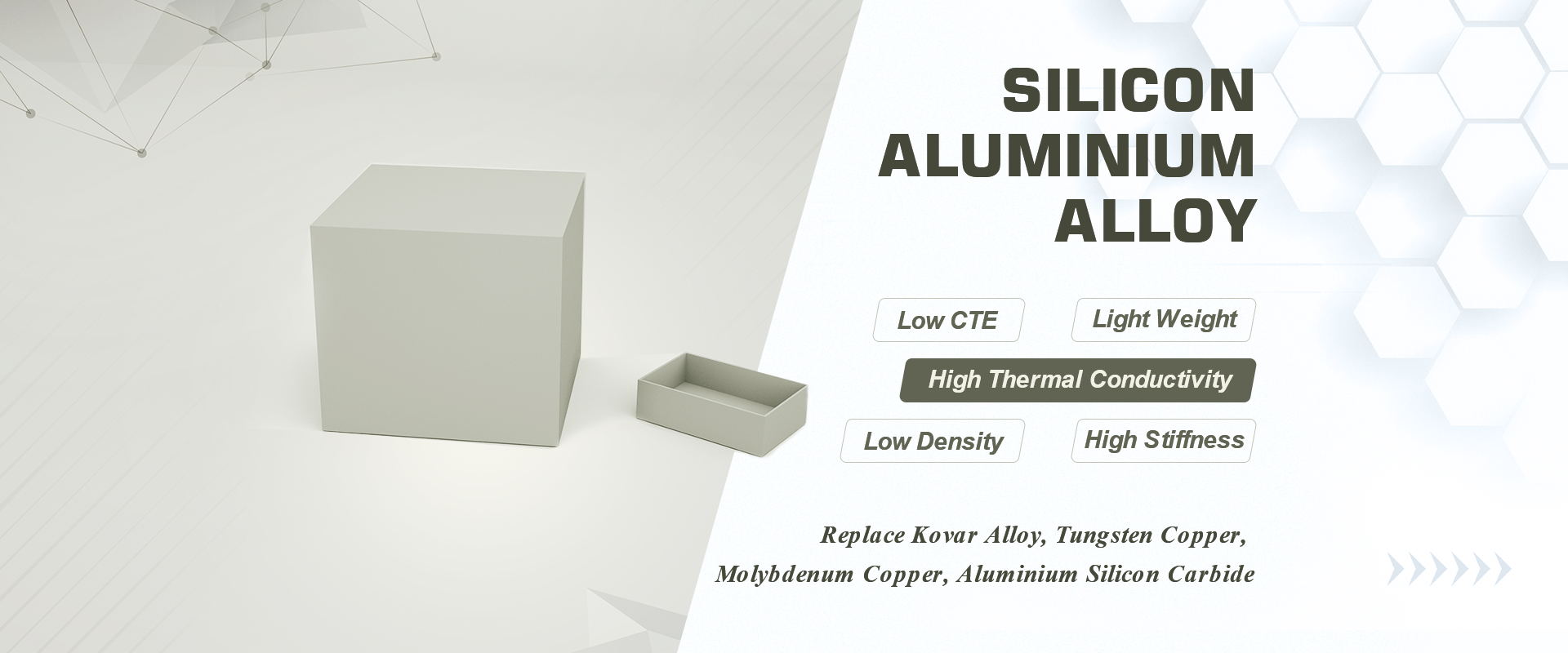

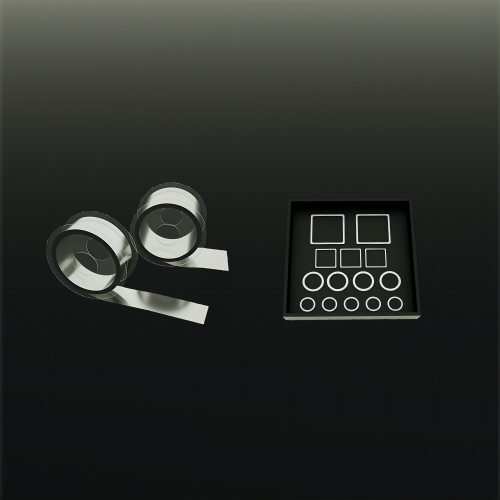

Chengdu Apex New Materials Co., Ltd., established in December 2016, is mainly dedicated to the research and development, production and sales of cutting-edge alloy materials. In 2017, the company introduced foreign alloy brazing material production equipment and established a professional R&D team. In the same year, it established a brazing material R&D center and a silicon-aluminum alloy R&D center. At present, in high-clean gold-based alloy solder (Au80Sn20, Au88Ge12, Au96.85Si3.15), other alloy brazing materials (Ag72Cu28, SAC305, Sn63Pb37, In97Ag3, Bi58Sn42 and other alloy brazing materials), pre-set gold-tin caps plates, silicon-aluminum alloys (AlSi27, AlSi50, AlSi70, Al4047) have all reached the international advanced level, and are committed to providing customers with more professional, efficient and reliable process solutions. In addition to providing a variety of standard and non-standard cutting-edge metal alloy materials, Apex New Materials can also meet customers' different product size and precision requirements, and customize special metal alloy materials for customers based on the characteristics of the solder itself. At present, the company's independently developed and produced products have been widely used in high-precision fields such as electronic packaging, microwaves, aerospace, optical communications, high-power power electronics, 5G, artificial intelligence, new energy vehicles, and medical equipment! “Eight Major Advantages” of Apex New Materials : 1. Independent research and development and solder customization Apex New Materials manufactures a variety of alloy solders and preformed alloy sheets based on gold, silver, lead, tin, indium and other non-ferrous metals. 2. Automation + advanced technology Through the continuous process improvement of Apex's new materials, the thinnest gold-tin solder sheet can currently reach 7um. 3. Rapid mold production Apex New Materials has a dedicated mold department with complete equipment and high-precision wire cutting processing capabilities. The production can be customized according to customer needs, and the mold opening cost is low. 4. Stamping Apex New Materials can quickly and efficiently produce products in a variety of standard, customized and complex shapes (discs, welded frames, rectangles, squares, circles and non-standard shapes, etc.). 5. High clean mirror effect, no oxidation The soldering technology independently developed by Apex New Materials has reached the advanced level abroad. It has the advantages of high cleanliness and non-oxidation, and can effectively solve problems such as gaps and poor wetting. 6. Have advanced production equipment Apex's new high-silicon aluminum alloy is produced using imported equipment. The metal material has uniform composition, refined structure, no macrosegregation, and low oxygen content. 7. Short delivery cycle Apex New Materials high-silicon aluminum alloy has a short supply cycle, and some models are in stock for a long time. Meet the urgent needs of customers. 8. Customization and supporting services Apex New Materials can provide a series of electronic packaging services such as post-machining, electroplating, and sintered insulators according to customer needs. We take "innovation, integrity, hard work" as our business philosophy, "gathering talents, innovation and efficiency, unity and advancement, and quality excellence" as our core values, and "creating a first-class high-end metal manufacturer of materials" as our corporate mission. Apex New Materials looks forward to working with you to create a better future!

- 2016

Founding Time

- 60

Employee Count

- 2000m²

Factory Covered

- 50+

Countries Served

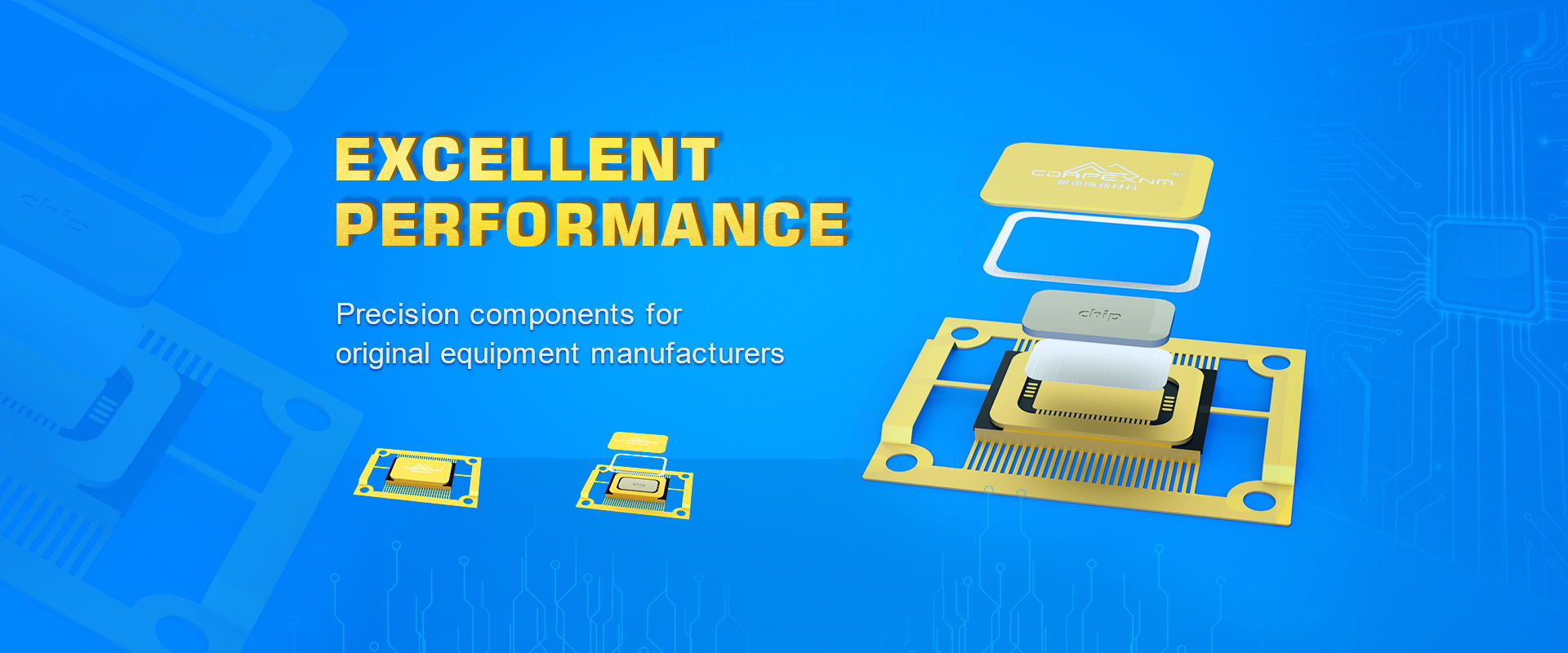

Products

Our advantage

-

self-development

Independent development and production -

Full range of products

A complete range of products -

Control of product quality

Control production schedule and product quality -

After-sales service

Provide post-production electronic packaging services -

Customized services

Customized product size -

7 micron ultra-thin gold-tin

The thinnest thickness of gold tin can reach 7um