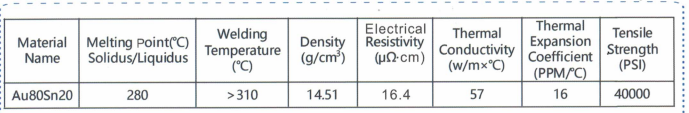

Au80Sn20 Solder Preforms

80Ay/20Sn has a melting point of 280'C (556'F). lt can be made into solder preforms with various options to addressspecific applications. Gold-tin solder preforms are generally used in applications that require a high meltingtemperature (over 150'C), good thermal fatigue properties, and high temperature strength. it is also used inapplications that require high tensile strength and high corrosive resistance, or in step soldering applications wherethe preform will not melt during a subseguent low-temperature reflow process. This alloy is suitable for fluxlesssoldering as wel. For these reasons, Gold-tin solder preforms are an obvious choice for die bonding applications.The inherent attributes of AuSn allovs are, prelerable for high power die, However, some alributes must beengineered into the preform in order to optimize performance.

Features:

*High strength *High thermal conductivity

*Corrosion resistant *Compatible with other precious metals

Performance:

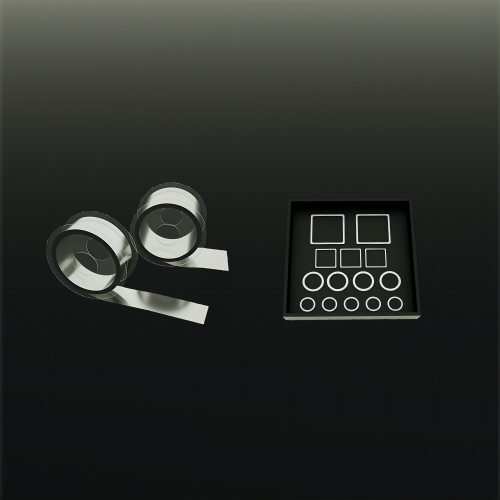

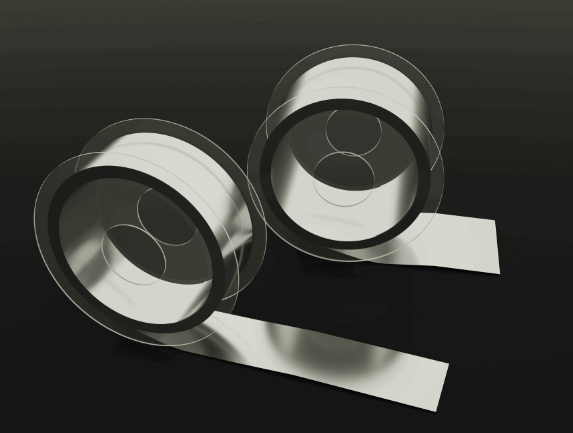

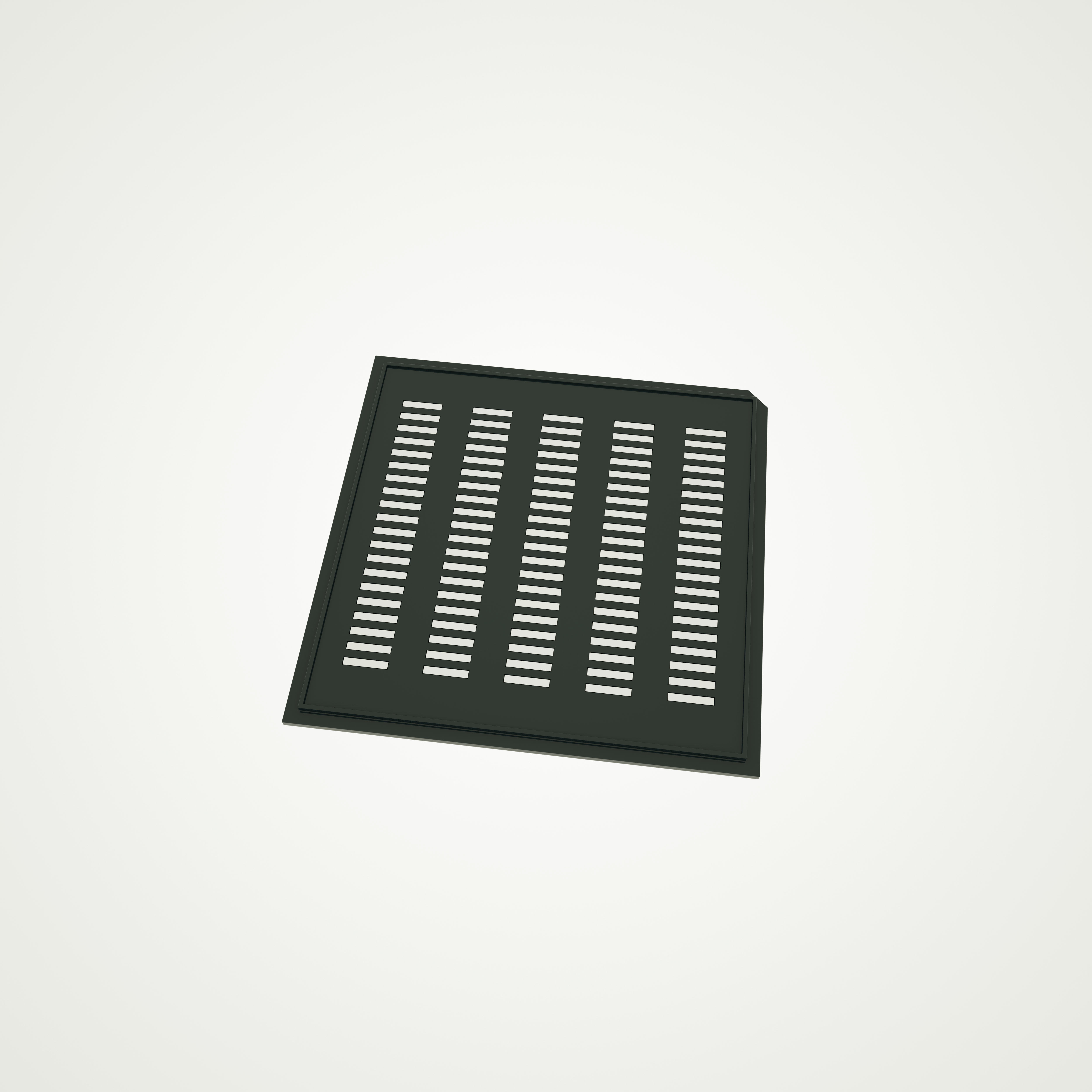

Geometry:

Guidelines for preform geometry can be derived from the die size. Generally, 90-100% of the die size wilindicate the preform x and y dimensions. As for thickness, a thinner bond line is desirable, but not whenreliability is sacrificed. The most critical attribute for die bonding application is flatness. Due to processconstraints, fixturing can be difficult and time consuming. Allowing the die to float freely on the preform can beadvantageous. lf the preform is not flat, it can skew the die at reflow and fail. Processing is the key topreserving flatness.

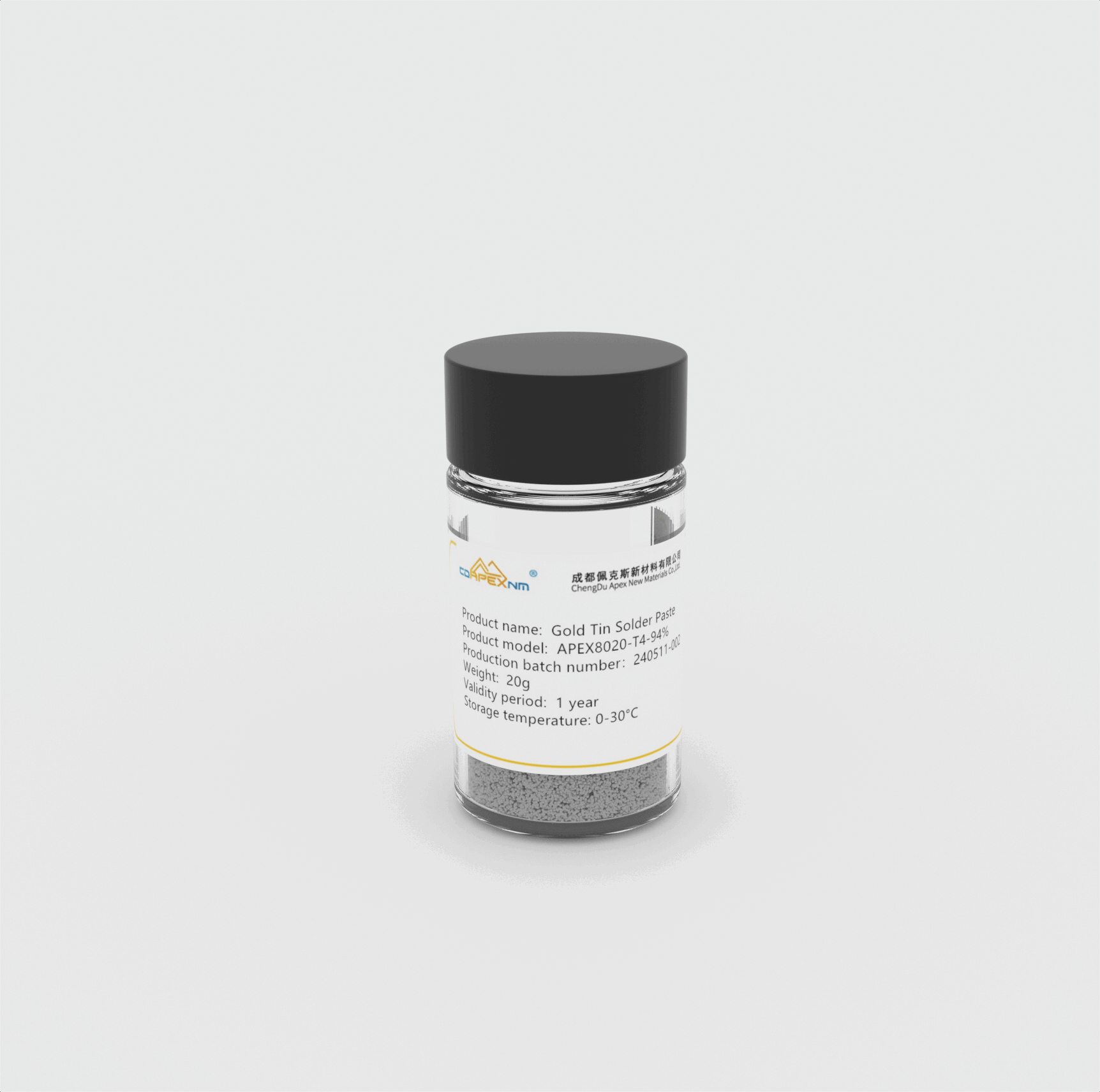

Packaging and Storage:

Apex New Materials product packaging usually depends on the size and shape of the product selected by customers.We currently have the following packaging methods :

AuSn Preform geometry is recommended to be stored in a non-corrosive atmosphere and dry enyironment, environmental relative humidity should not exceed 55%,the temperature is recommended to be lower than 22C or stored in inert gas,such as in a drying oven filled with nitrogen.

AuSnpreformsare an excellent choice for die attach to ensure good performance and irellability.

Thecorrectpreform characteristics and packaging ensure repeatablesuccess inaproduction process.