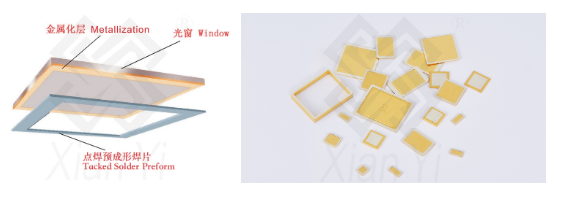

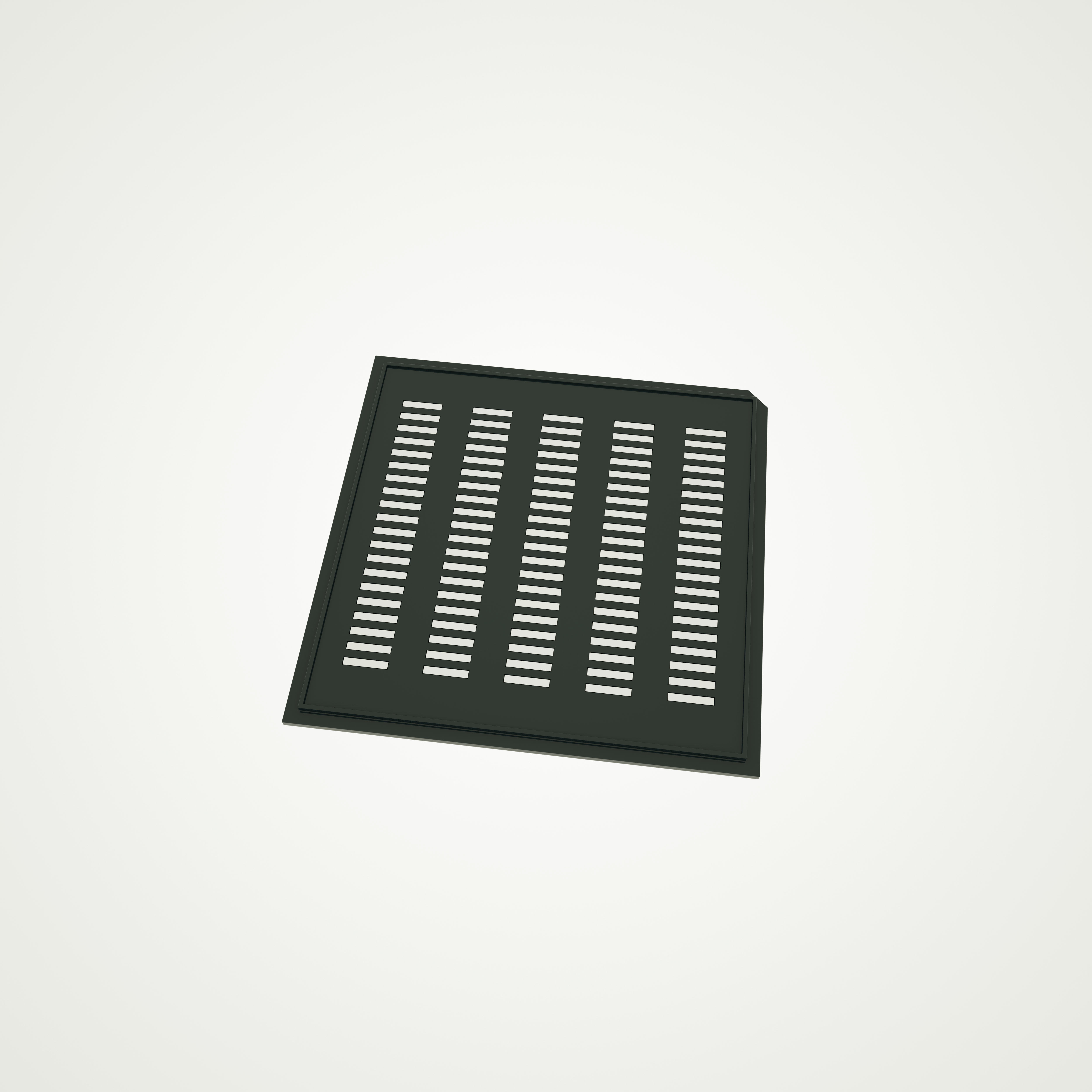

Preset gold tin cover plate

Kovar™ or Alloy 42, nickel plated, gold plated and spot welded to the solder preform. The nickel layer can inhibit corrosion, while the gold layer promotes solderability and extends shelf life, and the surface gold layer has good wettability with the gold-tin solder sheet, which can improve the reliability of the cover. Products have been widely used in hermetic packaging of microwave RF modules, FPGA special circuits, MEMS devices and optoelectronics.

Cover composition

Alloy: Typical Kovar Alloy™ or Alloy 42. Aluminum, titanium, stainless steel alloys and ceramics etc are available upon request.

Plating: Typically per QQ-N-290, nickel plating 50-350 micro inches thick, followed by MIL-G-45204, Type III, Class A, gold plating at least 50 micro inches thick. Other plating options including four-layer plating and customer-specific thicknesses are available upon request. The base will meet the requirements of MIL-M-38510.

[Tolerance] Length and Width ±.003"

【Thickness】±.001"

[Flatness] When the cap is smaller than .500”, the flatness is less than .001”; when the cap is larger than .500”, the flatness is less than .002”

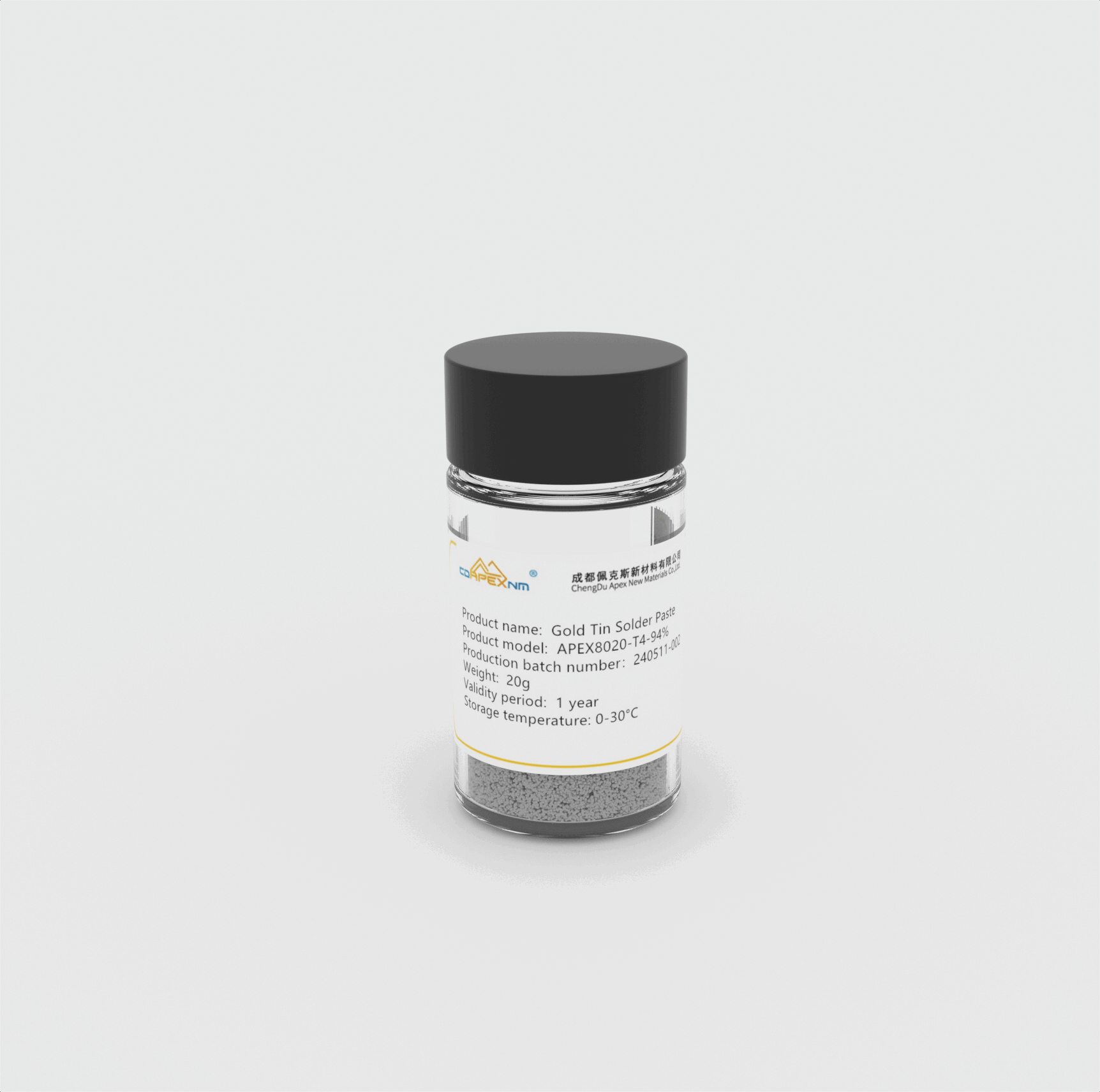

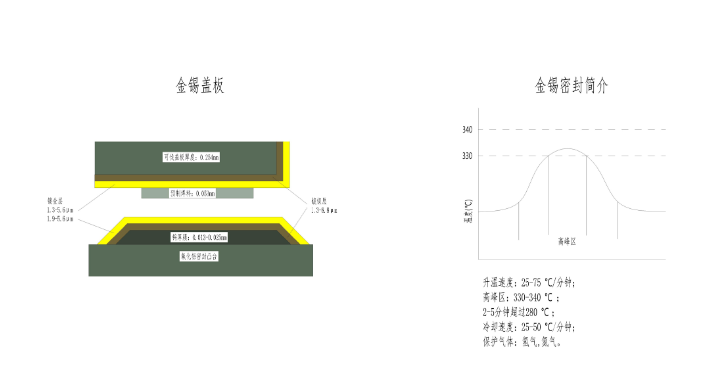

Au80Sn20 preform

【Length and width dimension tolerance】±.003""

【Thickness Dimension Tolerance】±.0003"

【Position welding assembly】Three integral welds aligned ±.005”, welding spatter <.003”

Features:

Cover plate six sides plating, salt spray resistance more than 24 hours

Precise presetting of solder

Small solder joint, no oxidation, no breakdown

High air tightness, corrosion resistance and reliability

Cover plate forming - electroplating - welding sheet forming - welding sheet presetting, the whole process of independent production

Fast delivery, 6-8 weeks

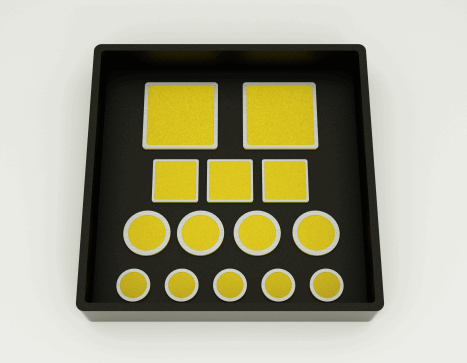

Typical application scenarios:

Airtight package