VR/waffle box packaging

Detailed Introduction:

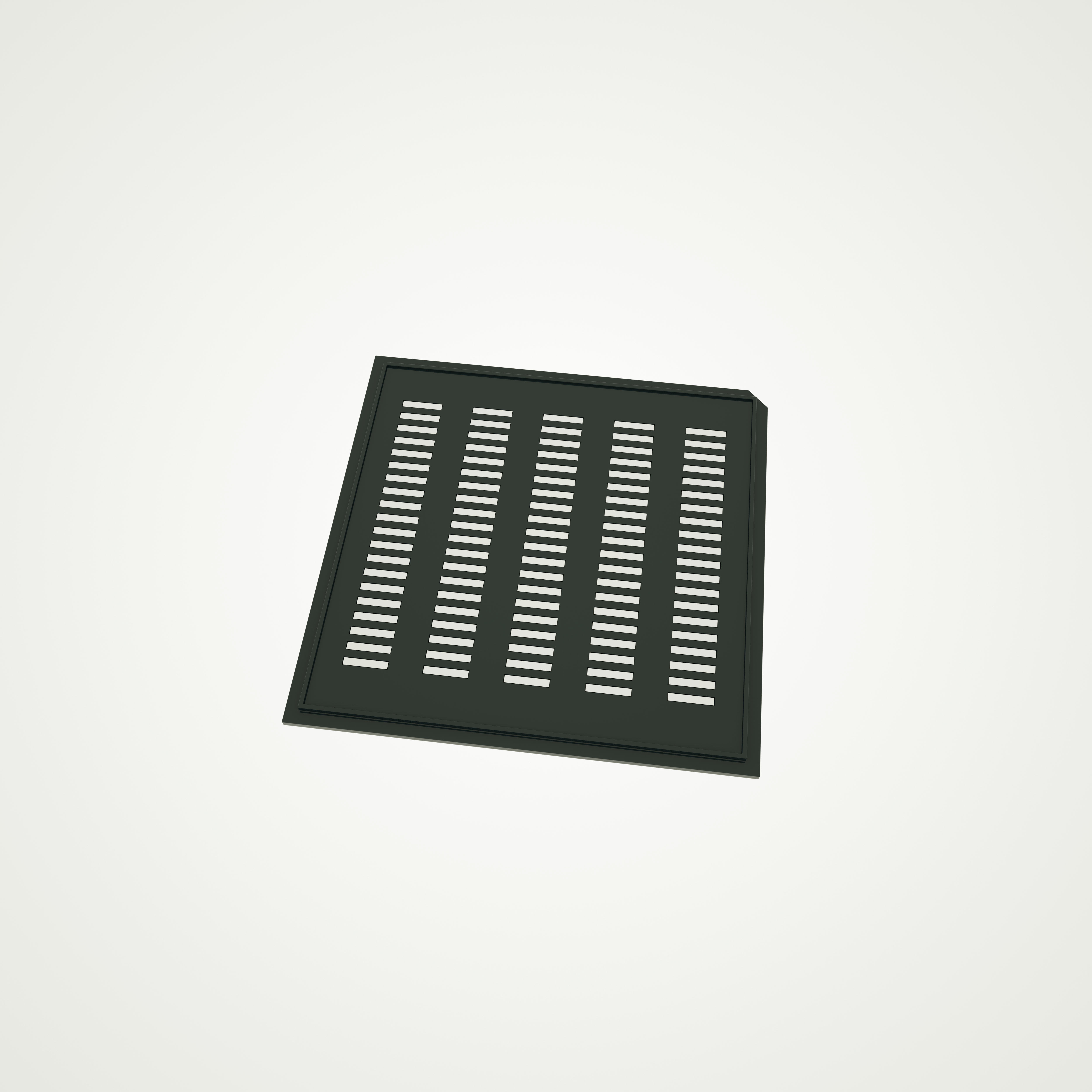

Chengdu Apex New Materials Co.Ltd. packages its parts in raised or recessed plastic trays called waffle boxes, which are convenient for packaging very small or unusually shaped parts. Waffle box packaging allows for automatic loading of parts. When the waffle box is filled, each recess contains a part that is properly oriented. The parts are usually covered with anti-static paper and foam-covered domes that are used to hold the parts in place. A lid then holds the waffle box together.

Advantages:

Eliminate or significantly reduce defects caused by the process, such as:

• Contamination during handling and transportation between operations.

• Mechanical defects such as bending, chips, warping, etc. caused by handling/packaging/transportation.

• When the parts are supplied in packaging suitable for automatic configuration, users can expand the range of materials and sizes used in automated processes.

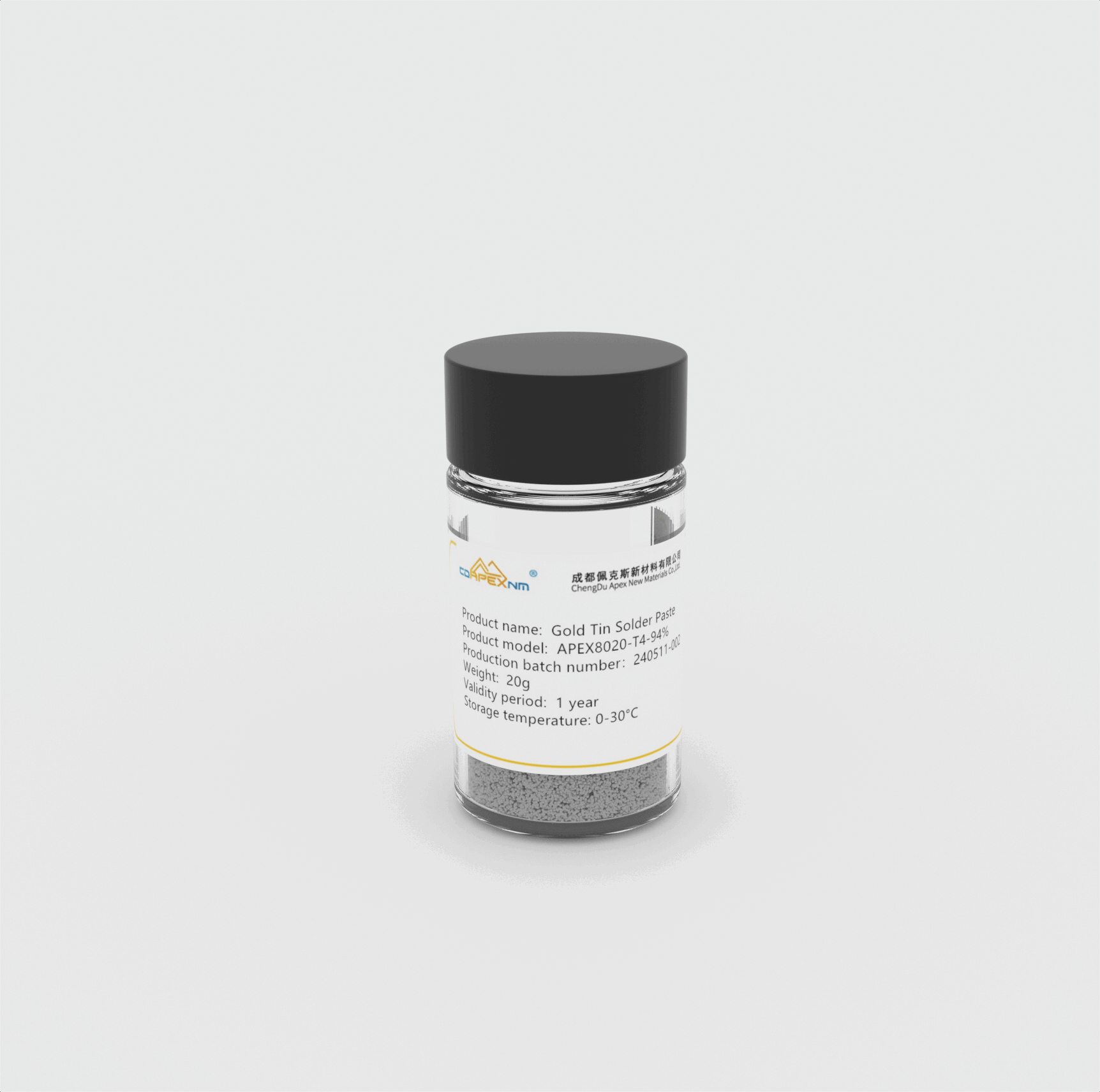

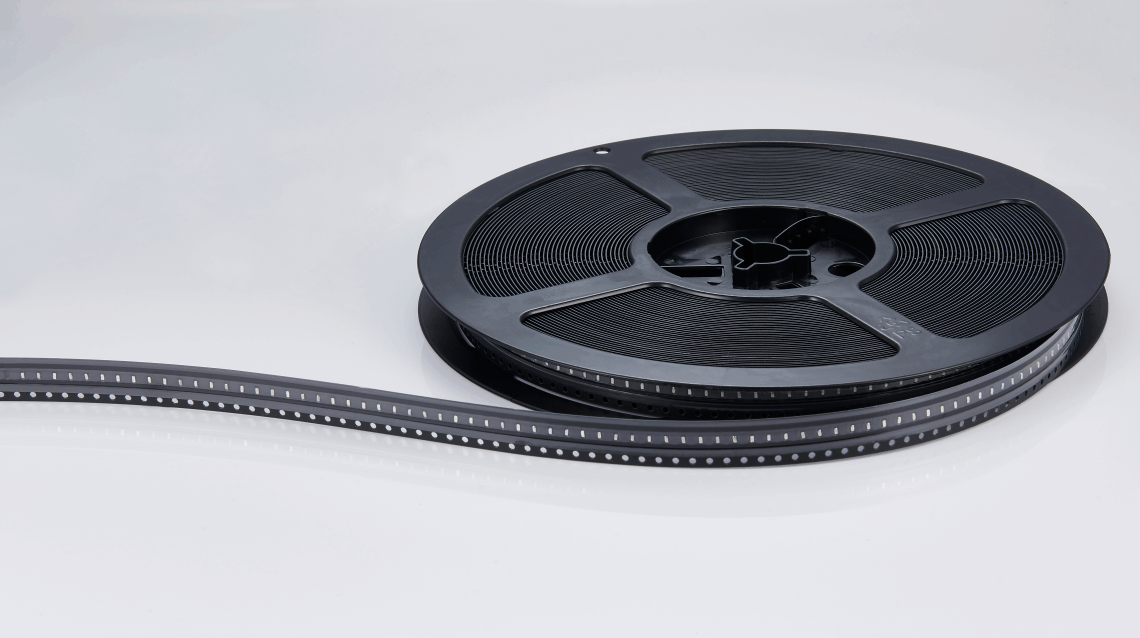

PACKING

Note:It is recommended that the preforms be stored in a non-corrosive, dry environment. The relative humidity should not exceed 55%, and the temperature should be below 22°C or stored in an inert gas, such as a dry box filled with nitrogen.