90% of People Don't Know These Amazing Characteristics of Copper-Aluminum Composite Materials

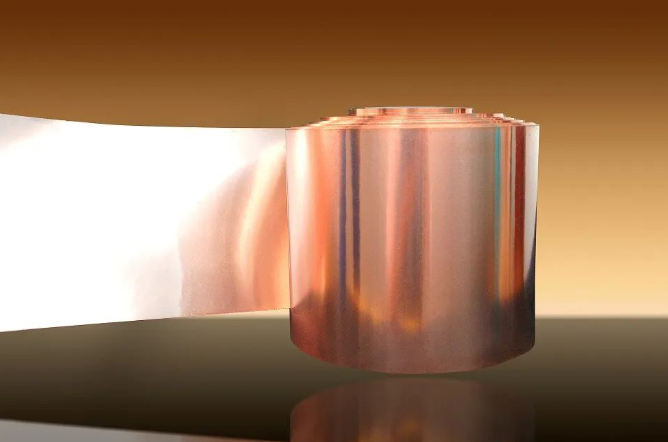

Copper-aluminum composite metal materials are made by composite processing of copper plates and aluminum plates under high temperature and high pressure through a certain process, forming a strong friction welding layer while producing a chemical reaction. Copper-aluminum composite metal materials have the advantages of both copper and aluminum, while overcoming the shortcomings of each of copper and aluminum.

Characteristics of copper-aluminum composite materials

- High strength

Copper-aluminum composite materials are composed of copper layers and aluminum layers through cold rolling, hot rolling or explosion welding, and have dual advantages. The aluminum layer has excellent properties such as light weight, high hardness, and high elastic modulus, while the copper layer has good electrical conductivity, thermal conductivity, and machinability. The strength of copper-aluminum composite materials is higher than that of single copper or aluminum materials, which makes it possible to use under heavy load or high stress conditions.

- High thermal conductivity

Copper-aluminum composite materials are composed of copper and aluminum materials and have good thermal conductivity. At high temperatures, the thermal conductivity of the aluminum layer is better, while at low temperatures, the thermal conductivity of the copper layer is better. At the same time, due to the combined structure of copper-aluminum composite materials, it can also operate in high temperature and high pressure environments, and is not easy to deform or melt.

- Corrosion resistance

Copper-aluminum composite materials have good corrosion resistance and can resist the erosion of various corrosive substances. The aluminum layer has a dense oxide layer that can prevent the copper layer from being corroded. At the same time, the copper layer also has a self-repairing function and can resist the occurrence of local corrosion. Therefore, copper-aluminum composite materials can be used in harsh environments.

- Wear resistance

Since copper-aluminum composite materials are composed of two different materials, their wear resistance is better than other materials. Under the erosion of high-speed fluids, the combined structure can effectively prevent the surface loss of the material, thereby ensuring its long-term durability.

- Impact resistance

Copper-aluminum composite materials can obtain good formability during casting, punching, edge pressing and other processes. At the same time, due to the different strength and toughness of copper and aluminum, the combined material also has higher impact resistance. This makes copper-aluminum composite materials widely used in aviation, aerospace, automobiles, electronic equipment and other fields.

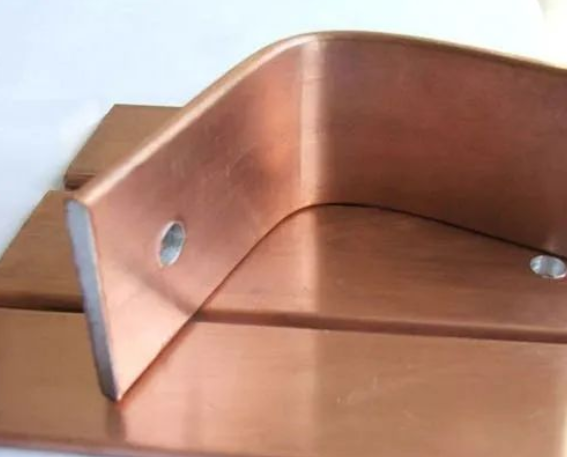

Copper-aluminum composite busbar

Copper-aluminum composite busbar solves the two major problems of copper-aluminum composite, that is, copper and aluminum are easy to oxidize and the oxide film is difficult to remove, and that copper-aluminum composite is easy to produce intermetallic compounds (Al2Cu) at low temperatures. According to SEM analysis, the thickness of the transition layer between copper and aluminum in traditional copper-clad aluminum busbars is 1550 μm, while the thickness of the transition layer between copper and aluminum in the new copper-aluminum composite busbar is only 12 μm, which is much lower than that of traditional copper-clad aluminum busbars. It not only realizes the metallurgical bonding between copper and aluminum, but also ensures the bonding strength between copper and aluminum, and solves the problem of high resistivity of the transition layer. It has excellent comprehensive performance, and its bending, drilling, punching and other performances are the same as pure copper, and its density is low.

Double-sided copper-aluminum composite busbar

Double-sided copper-aluminum composite busbar has a thickness of 3.015.0mm; width ≤500mm, technical parameters: composite strength: ≥12N/mm, shear strength: ≥35MPa, tensile strength: 90150MPa, elongation: 0~35%, DC resistivity: ≤0.02450mm2/m surface conductivity: ≥98%, rated current temperature rise: ≤65℃; application field: conductive industry (can be widely used in high and low voltage distribution cabinets, complete sets of switches, bus ducts, electrolytic cells, etc.).

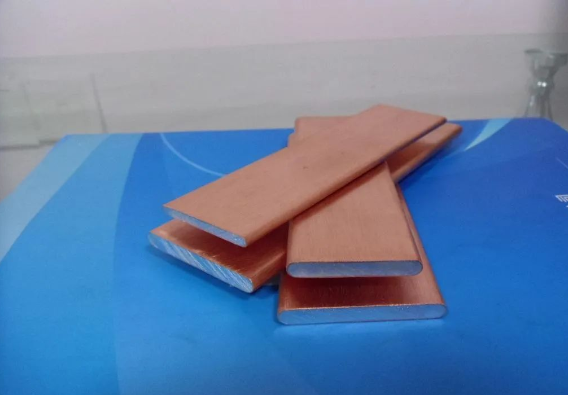

Copper-clad aluminum busbar

With the rapid development of the new energy vehicle industry, the PACK connection problem of lithium batteries has become more and more prominent. Many bus battery packs have upper dry packs, and the positive and negative electrodes of the single cells are made of aluminum foil and copper foil. How to achieve reliable, light, and simple series and parallel connection of lithium battery packs is a bottleneck technology that restricts the development of lithium battery vehicles. Through independent innovation, two copper-aluminum composite materials for lithium battery connection have been developed.

Copper-aluminum composite base column material and copper-aluminum composite transition sheet. Base column material: The copper-aluminum composite base column material is made of 3mm copper and 10mm aluminum plate, and the copper negative electrode is connected, while the aluminum and the outer aluminum plate are connected to form a battery pack. The two exposed electrodes are both aluminum and can be connected by normal laser welding process; connecting sheet material: a 10mm copper strip is compounded in the middle of the aluminum plate to reach the aluminum plates on both sides to complete the series and parallel connection between the single cells. Composite strength: ≥100MPa high composite strength, realizing the metallurgical bonding between copper and aluminum.