Application of preform solder sheet process

Application of preform solder sheet process

Preform solder sheet, Solder Preform. It is a solder that has been made into precision shape and is suitable for large-scale manufacturing processes with small tolerances. Preform solder sheet is an ideal solution for applications such as PCB assembly, automotive parts components, connectors and terminal equipment, chip connection, power module substrate attachment, filter connectors and electronic component assembly, especially suitable for mixed and separate component assembly and surface mounting technology.

Process advancement:

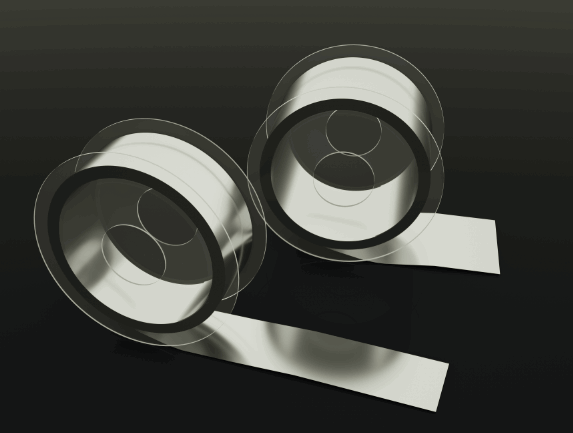

A wide variety of shapes and sizes

Preform solder sheet Solder Preform has various traditional shapes, such as ring, circle, square, rectangle, disc, etc. The minimum size range can be 0.010 inches square or 0.010 inches in diameter, and it is kept within a very small tolerance range to ensure the accuracy of solder volume. In addition, users can also use solder tape to make their own preforms. See below for a list of preform solder sheets of various shapes and their sizes. .

Solder Preform Standard Specifications | ||

Preform: | smallest size: | 0.010 inch diameter or square |

Thickness tolerance: | 0.010 in. to .060 in. ± 0.001 in. | |

>0.060 in. ± 0.002 in | ||

Size tolerance: | 0.001" to 0.002" ± 0.0002" | |

0.002" to 0.010" ± 0.0004" | ||

0.010" to 0.020" ± 0.001" | ||

>0.020 inches ± 0.002 inches | ||

spherical: | Minimum diameter: | 0.003 inches ± 0.0005 inches |

2. Higher welding reliability

Preform solder washers are not only ideal for through-hole connections that meet precise solder volume and flux requirements, but also eliminate the need for secondary soldering processes. Preforms can be placed on connector pins during board assembly using pick and place equipment. Solder washers can also be incorporated into the production process in a variety of other ways. Connector pins are reflowed at the same time as solder paste.

Preforms can be used with solder paste to strengthen solder joints. In existing SMT processes, the volume of alloy used for soldering in solder paste is only half of the volume of solder paste due to the thickness of the template, so sometimes solder paste does not provide enough solder volume, and solder joint strength and solder coverage cannot meet the requirements. However, after the introduction of preforms, solder paste can be applied to the circuit board, and then the preform can be placed on the solder paste or inserted on the pins of the paper, and then the device pins can be inserted into the printed board to achieve good solder filling after one soldering.

Solder washers in preforms are not only ideal for through-hole connections that meet precise solder volume and flux requirements, but also eliminate the need for secondary soldering processes. Through the pick-and-place equipment, the preformed solder washers are placed on the connector pins during the circuit board assembly process, and the connector pins are reflowed at the same time as the solder paste.

In addition, by using pre-set preforms, reliable soldering can be performed on difficult-to-operate parts, and flux coatings such as rosin/resin can be added to form a complete soldering system.

3. Easy to assemble, greatly improved economic benefits

(1) Diversity of packaging methods. Preformed solder sheets can be packaged according to customer requirements. Preformed solder sheets that are not easy to deform can be packaged in cans, and when used, preformed solder sheets can be distributed with tweezers or vacuum pick-up tools. When the amount is large, preformed solder sheets can be packaged in tape and reel packaging and mounted using automatic mounting processes without human intervention.

(2) The application of preformed solder sheets greatly improves economic benefits. After applying preformed solder sheets, since the predetermined amount of solder does not depend on personal judgment and the operation is simple, highly skilled operators are not necessarily required. This leads to a large amount of manpower savings. Since preformed solder sheets usually produce uniform solder joints, the final inspection step can also be simplified.

(3) Although the initial cost of preforms is somewhat higher than that of bulk solder, the savings in the production process can offset the increased expenses.

4. Application process requirements

(1) Space guarantee. When designing and using preforms, be sure to provide sufficient space between materials to ensure proper wetting. It is best to leave about 0.003 inches and provide natural boundaries (such as grooves, shoulders and grooves) to keep the solder from shifting. This protects the solder from escaping from the solder joint under the influence of gravity or capillary action. Because gases expand and contract during heating and cooling cycles, solder joint designs that may trap air should be avoided. Trapped air can cause solder splashing or cause sand holes in the solder joint.

(2) Solder quantity and tool selection. The required amount of solder must be accurately set so that the preformed solder piece can produce proper embedding and meet process requirements. In addition, preforms are also very suitable for delivery equipment such as rotary or linear vibration feeders, special vacuum pickup manifolds and barrel-type individual feeders. Preforms can also be effectively used with manual assembly techniques such as tweezers and vacuum pick-up.

(3) Confirm welding parameters and solder selection. When determining which preform to use, the first consideration is the melting temperature and surface compatibility of the parts to be welded. Next, consider the size required to form the weld. If the selected size is larger than the actual required specification, it will increase costs. Preforms can be welded by conduction, convection, induction and radiation heating. Of course, the specific heating method depends on the melting point of the preform, the surrounding materials and the configuration of the weld.

(4) Study packaging parameters. The larger the number of preforms per package, the lower the unit cost. When selecting a package, the shape, brittleness and purity of the preform are all factors to consider. Alloys that are easily oxidized are often packaged in an inert gas (such as argon).

(5) Batch production, better cost. Using preforms with automated placement technology and batch production heating technology can greatly reduce costs. The larger the number of preforms per package, the lower the unit cost.

Apex-New Material specializes in the introduction of preform production equipment, which has reached the international advanced level and seamlessly replaces the vacuum eutectic furnace for vacuum reflow soldering of preform imported from Europe and the United States. If you have any questions about vacuum soldering of preforms, please contact our technical experts.