Au-Sn gold tin eutectic solder and its application

Au-Sn gold tin eutectic solder and its application

If the ceramic package shell welding, under the premise of high reliability, air tightness, high heat dissipation, lead-free, corrosion resistance, high creep resistance, select the appropriate solder, reduce the welding temperature, then you can greatly shorten the entire brazing process, greatly shorten the working time, reduce energy consumption costs.

▌ Traditional solder

β-Sn has a body-centered tetragonal structure, and α-Sn has a diamond cubic structure. During the cooling process, the pure Sn solder will undergo a phase transition from the white β-Sn phase to the gray α-Sn phase (volume expansion of about 26%), which will destroy the integrity of the structure, resulting in the appearance of "Tin Pest".

Because of the low melting point and coarsening at high temperature, the traditional eutectic SnPb solder is easy to cause the deterioration of mechanical properties, and can not meet the requirements of automotive, avionics and other applications.

▌Au-Sn alloy

Because Au has good corrosion resistance, it can prevent welding reliability problems caused by solderization. At the same time, the Au element can be quickly dissolved in the liquid SN-based solder, which greatly improves its wettability, so that the AuSn alloy solder has the advantages of high reliability, high strength, and excellent corrosion resistance, fatigue resistance and other characteristics. Among them,Au80Sn20 alloy is the only solder that can replace high melting point PB-based alloy within 280℃~360 ℃.

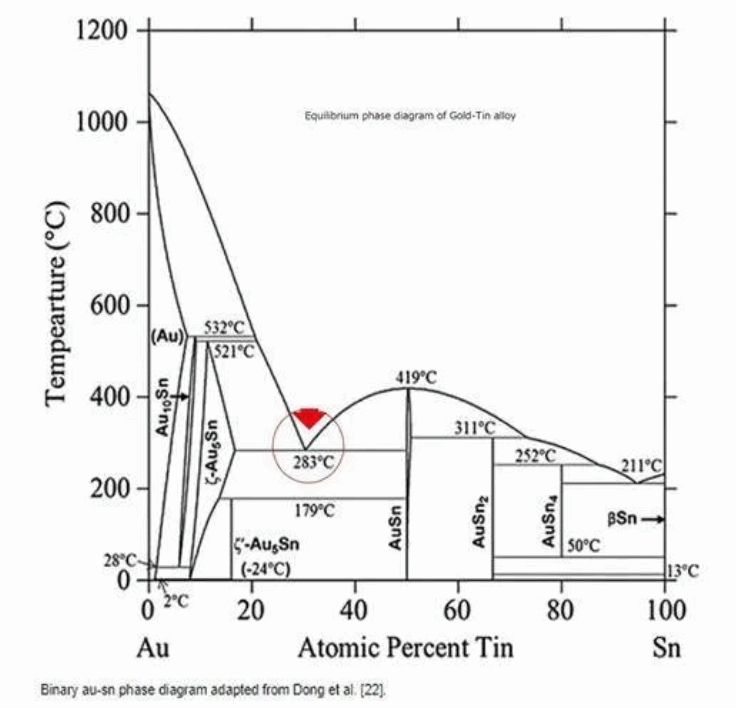

At present, the widely used Au-Sn alloy phase diagram is the Au80Sn20 alloy phase diagram obtained by Okalnoto et al from experimental data in 1987, as shown in Figure 3.

It is known that the melting point of Au80Sn20 (mass fraction: Au80%, Sn20%) eutectic alloy is 283℃, and the actual welding temperature is about 300 ~ 310℃, which makes the welding process control more accurate and helps to improve the welding quality.

▌AuSn solder preparation method

Most of the Au80Sn20 eutectic pads used in China are preformed, and the thinnest thickness of the preformed pads is 25μm. The traditional gold tin alloy welding pad is preformed, and its processing technology is physical powder metallurgy. Of course, there are casting drawing rolling method and laminated cold rolling composite method. The third component Pd or Pt needs to be added in the casting drawing rolling method, but it is difficult to control the reaction amount of gold and tin accurately by the laminated cold rolling method.

In addition, the combination of environmentally friendly cyanide-free gold citrate (Au+) and tin sulfate (Sn2+), under the action of special complex agent, can achieve the deposition of Au80Sn20 eutectic on the specified package micro-region of the ceramic substrate, and the eutectic thickness can be controlled by the electrodeposition time, melting point temperature < 300℃. Pad thickness can be accurately controlled in the range of 1μm~20μm.

▌ Application Areas

Gold tin eutectic solder is widely used in the field of electronic packaging, in airtight packaging, RF and microwave packaging, LED, lead insulator welding, flip chip, laser diode, 3-D chip level packaging and so on. Especially in the case of high reliability requirements. Here are a few main application areas:

Optoelectronic packaging

Gold tin eutectic solder has become the preferred material in the package of optoelectronic devices because of its good physical properties and moderate brazing temperature. It can be welded directly to the gold layer at around 300 ° C without flux, which is essential for the packaging of high-power optoelectronic devices such as leds, lasers and optical communication devices.

Semiconductor packaging

In the semiconductor industry, gold-tin eutectic alloys are used to connect chips and ceramicsubstrate (ID:ceramicsubstrate) carriers, whose high strength and good thermal fatigue resistance ensure reliability in harsh weather conditions. At the same time, its excellent flood performance and high thermal conductivity are also indispensable features in semiconductor packaging.

aerospace

In the aerospace sector, electronic devices often face extreme temperature changes and vibration environments. The high strength and thermal fatigue resistance of gold-tin eutectic alloys make them ideal for these applications.

War industry

Military electronic equipment requires a high degree of stability and reliability, and the physical properties of gold-tin eutectic alloys can meet these requirements, so they are also widely used in this field.