Main limitations and defect types of high-strength aluminum alloys in additive manufacturing applications

Main limitations and defect types of high-strength aluminum alloys in additive manufacturing applications

In the past two decades, additive manufacturing processes have been widely used to manufacture complex-shaped components in many industrial fields, one of the main application areas is the aerospace industry. High-strength aluminum alloys are widely used in the aerospace industry due to their extremely high strength-to-weight ratio and excellent machinability. However, the applicability of additive manufacturing processes for high-strength aluminum alloys is still limited by several non-negligible problems and defects in the additive manufacturing process. Over the years, efforts have been made to reduce or eliminate these defects, thereby expanding the scope of application of additive manufacturing in high-strength aluminum alloys.

Main limitations of high-strength aluminum alloys in additive manufacturing applications

The use of high-strength aluminum alloy 3D printed components in the aerospace industry is still limited due to certain types of defects that affect the quality of this technology. Another key issue is the lack of comprehensive and recognized quality standards for 3D printed components, which limits the use of this process in the aerospace industry. Currently, only a very small number of aluminum alloys can be properly modified, and 2xxx and 7xxx series alloys are difficult to process by 3D printing due to solidification-related issues caused by the thermal cycles that occur during the 3D printing process. Various types of defects have been observed in 3D printed 2xxx and 7xxx high-strength aluminum alloy products. In order to eliminate or avoid defects and overcome processing difficulties, it is necessary to modify the chemical composition of the alloy and develop relevant domestic processes.

The reasons why the aerospace industry has not widely used 3D printing processes to produce high-strength aluminum alloy structural parts mainly include the following aspects:

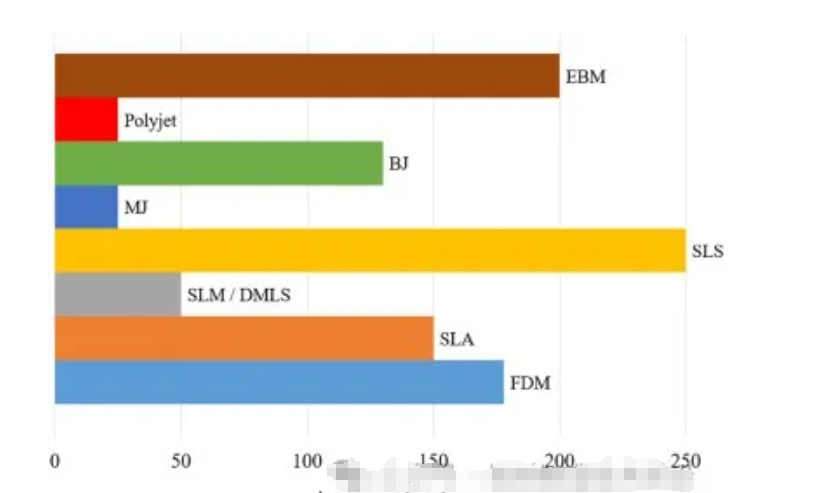

The 3D printing process is limited by the size of the part and the production speed, resulting in the process not being competitive in the production of large aerospace parts. For example, the largest aviation part produced by the additive manufacturing process weighs about 750 kg, is 4.7 m long, 1.7 m wide and 0.5 m high. The part is designed to demonstrate the application of 3D printing in the production of components for the next generation Boeing 777x jet. However, this is far from the 64.3 m wingspan of the Boeing 747 passenger aircraft. The two most important priorities of the aerospace industry are safety assurance and risk management, which require aerospace parts to have high precision and consistency. However, only a few 3D printing processes can currently produce components with a dimensional tolerance of 30–40μm, but the dimensional tolerance of components required by aerospace companies is usually less than 10μm. Therefore, the required dimensional accuracy of aerospace components cannot be obtained every time, and machining the parts to achieve the required dimensions results in additional manufacturing steps and costs.

Aerospace components have a strict quality certification system, which is very important for critical components such as engine turbine blades. However, the quality management and certification methods of 3D printing in the aerospace industry are still being developed, and the complexity lies in the lack of understanding of the failure mechanisms of additively manufactured aerospace components, especially fatigue failure.

In recent years, many standards related to metal additive manufacturing have been established. However, only a few of them are applicable to the aerospace field, including SAE AS9100 and MSFC-STD-3716. The lack of standards has seriously affected the widespread application of 3D printing processes, and manufacturers have also focused on developing such standards to promote technological development. At the same time, due to the complexity of the physical process in the additive manufacturing process, existing non-destructive testing methods may have problems in the detection of defects such as pores, gas inclusions and cracks, and special test methods need to be developed.

Main defects generated in the additive manufacturing process of high-strength aluminum alloys:

Due to the manufacturing process and the characteristics of the alloy itself, several types of defects occur in 3D printed parts of 2xxx and 7xxx high-strength aluminum alloys, including cracking, porosity, spheroidization, and oxidation and evaporation of volatile alloying elements.

1. Cracking

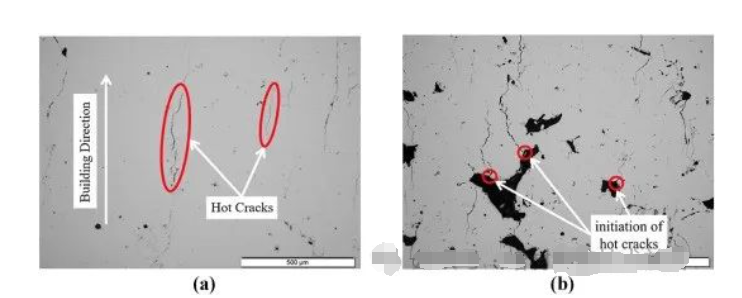

Cracks can occur in the 3D printing process for a variety of reasons, including the presence of pores (which act as the starting point of cracks) and the effects of heating and solidification during the manufacturing process. Cracks in the aluminum alloy 3D printing process can be divided into liquefaction cracks and solidification cracks. Liquefaction is the selective melting of certain components in the microstructure when heat is applied. For example, second phase particles with a low melting point or grain boundaries with a high degree of segregation may have a much lower melting point than the matrix, and therefore begin to melt locally, resulting in debonding at these locations. The tendency of liquefaction cracking is related to the high concentration of alloying elements and the high thermal conductivity characteristics of heat-treatable aluminum alloys, as well as high laser power and/or high scanning speed. In contrast, solidification cracking occurs in the final stage of solidification, when the liquid flow is insufficient to fill the gaps between the solidifying metal. This type of crack is associated with a larger solidification range. Solidification cracking is a very common phenomenon in the additive manufacturing of high-strength aluminum alloys, especially for 2xxx aluminum alloys. During the solidification of the alloy, columnar grains expand along the thermal gradient and shrink along the grain boundaries, resulting in crack formation. The formation and propagation of solidification cracks can be observed along the grain boundaries in the final stage of solidification.

2. Porosity

Pore is one of the most common metallurgical defects in the additive manufacturing of high-strength aluminum alloys, especially when lasers are involved. It can be divided into shrinkage pores, pores, and fusion defects. Several factors related to the formation of pores include scanning strategy, thermal cracking, scanning speed, and the shielding gas used. Even if the process parameters are optimized, a certain degree of porosity can still be observed. In the SLM process, common types of pores are keyholes and metallurgical pores. The pores formed after laser scanning will remain below the surface of the part, among which keyholes (> 100μm, irregular shape) are mostly formed at fast laser scanning speeds, while metallurgical pores (<100μm, spherical) are mostly formed at slow scanning speeds. Other types of pores may occur due to incomplete melting of aluminum alloy powder or poor fusion between layers.

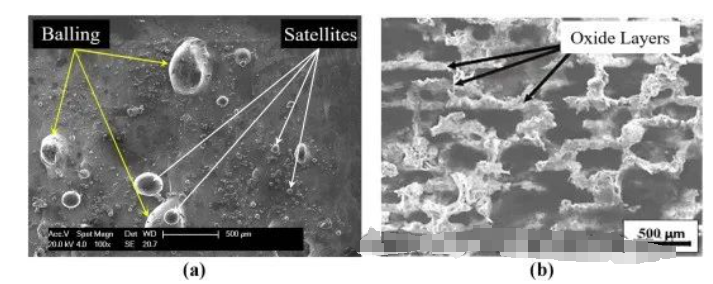

3. Spheroidization and satellite spheres

Considering the principle of minimum surface energy, when the contact with the substrate is poor, the liquid metal in the 3D printing process may shrink into a spherical shape due to surface tension, which is the spheroidization phenomenon. Spheroidization can cause poor fusion of the aluminum alloy surface and rough surface of the solidified layer, resulting in reduced part quality. The spheroidization of high-strength aluminum alloys in the 3D printing process is usually related to the melting process. At the same time, droplet splashing and poor wettability may also lead to the formation of spheroidization. When a sufficient melting level is reached in the lower molten pool, the spheroidization phenomenon will weaken. The formation of satellite balls is another surface defect that is slightly different from spheroidization in terms of microstructure and morphology. Satellite ball surface defects consist of particles adhering to the surface layer and are highly dependent on the scanning speed. Studies have shown that at a scanning speed of 250 mm/s, much less satellite ball formation was observed in AlSi10Mg than at 500 mm/s or 750 mm/s.

4. Oxidation

Another issue that reduces the quality of aluminum alloy 3D printed parts is the oxidation that occurs during the printing process.

The thermodynamic stability of aluminum oxide makes it difficult to remove the oxide film produced on the surface of aluminum alloy powder. Some researchers analyzed the formation mechanism of oxide scale at various points in the molten pool during laser fusion of 6061 aluminum alloy and Al-12Si. In their study, the oxide scale on the surface of the molten pool evaporated after laser irradiation, and it was determined that the Marangoni force that stirred the molten pool was the most likely cause of the destruction of the oxide scale. The oxide formed regional pores due to the residue on both sides of the molten pool.

During the printing process, although the chamber is filled with inert gas, there is still 0.1–0.2% oxygen remaining in the powder, which also leads to oxidation during the layer-by-layer melting process. In addition, oxidation will cause the alloy powder to agglomerate, making the powder laying uneven, resulting in reduced structural integrity and precision of the part.

The melting and wetting of different regions of aluminum alloys are controlled by the dissociation or destruction of oxides, rather than by the melting of different regions. By controlling the formation of oxide films, the quality of aluminum alloy printed parts can be adjusted. Therefore, it is necessary to pay close attention to the oxygen content during the printing process.

5. Evaporation of volatile alloying elements

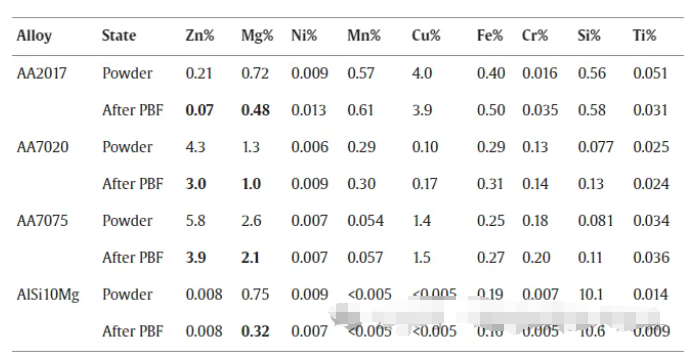

In additive manufacturing processes with relatively high power density, selective evaporation may occur if the melting point of some elements in the alloy is lower than that of the alloy parent material. The composition changes caused by evaporation will change the corrosion resistance, mechanical properties and solidification structure of the material. At present, research focuses on the evaporation of volatile alloying elements (such as Zn, Mg and Li) during SLM processing of high-strength aluminum alloys, with the aim of improving the processing performance of the material. Researchers have evaluated the suitability of several high-strength aluminum alloys for SLM, and the chemical composition after printing has changed significantly, especially the content of zinc and magnesium.

In the past two decades, additive manufacturing processes have been widely used in many industrial fields to manufacture complex-shaped parts, one of the main application areas is the aerospace industry. High-strength aluminum alloys are widely used in this field due to their extremely high strength-to-weight ratio and excellent machinability. However, the applicability of additive manufacturing processes for high-strength aluminum alloys is still limited by several non-negligible problems and defects. Over the years, people have worked hard to reduce or eliminate these defects, thereby expanding the scope of application of additive manufacturing in high-strength aluminum alloys.