What are copper composites?

What are copper composites?

Copper composites are a class of materials that improve certain properties of copper or enhance its functions by combining copper with other materials. These composites can be used to overcome the inherent shortcomings of a single metal or material while retaining the excellent properties of copper, such as electrical conductivity, thermal conductivity, corrosion resistance, etc. In the field of modern industry, with the continuous advancement of science and technology, the demand for innovation and optimization of materials is increasing, and copper composites have become an advanced material widely used in multiple industries, especially in the fields of electronics, electrical, aerospace and automobile manufacturing.

Definition and classification of copper composites

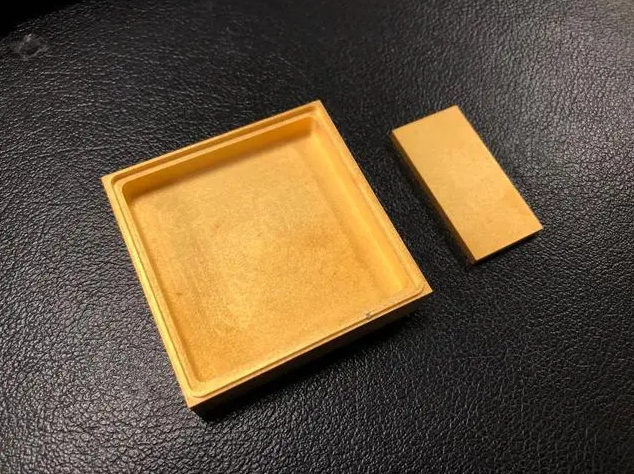

Copper composites are composites formed by combining copper with other materials (such as metals, ceramics, carbon materials, etc.) to optimize their physical, chemical and mechanical properties. Common copper-based composites include copper-aluminum composites, copper-graphite composites, copper-ceramic composites, etc. Different composite methods can give copper materials different functions and properties, making them suitable for different occasions.

1. Metal-based copper composites: copper is compounded with other metal elements, such as aluminum, magnesium or titanium. Such materials usually have high conductivity and good mechanical strength, and have significantly improved corrosion resistance. Copper-aluminum composites are widely used in high-voltage cables and automotive parts because of their high conductivity and light weight.

2. Ceramic-based copper composites: The composite of ceramic and copper can improve the hardness, wear resistance and high temperature resistance of the material. Copper-ceramic composites are widely used in aerospace, nuclear industry and electrical equipment in high-temperature environments. Such materials usually have high oxidation resistance and can maintain stable functions in harsh environments.

3. Carbon-based copper composites: The combination of carbon fiber or graphite and copper can significantly improve the self-lubricity and wear resistance of the material. Copper-graphite composites are often used in high-voltage electrical contactors and slip rings because graphite has good lubrication properties and can reduce friction and wear.

Manufacturing process and technical challenges

The manufacturing process of copper composites is complex and requires consideration of the compatibility between different materials and how to maximize their respective advantages. Common manufacturing processes include powder metallurgy, casting and spraying.

1. Powder metallurgy: By mixing copper powder and powder of other materials, and then pressing them at high temperature. This process is often used to produce composite materials with fine structures and can control the microstructure of the material to optimize performance. The advantages of powder metallurgy are good material uniformity and high manufacturing precision, but its difficulty lies in the different thermal expansion coefficients of different materials, which are prone to stress concentration at high temperatures, leading to material damage.

2. Casting method: by melting copper and other materials, mixing them, and casting them into shape. This method is suitable for large-scale production, but due to the poor compatibility of different materials in the molten state, it is often easy to produce stratification and segregation, affecting the performance of the composite material.

3. Spraying method: Spray another material onto the surface of copper at high temperature or high pressure to form a composite layer. This process is suitable for manufacturing composite materials with special surface properties, which are commonly used in conductive components in the electronics industry.

However, the manufacture of copper composite materials also faces many technical challenges. For example, how to improve the interface bonding strength between different materials, how to control the difference in thermal expansion coefficients of materials, and how to avoid the destruction of material structure during the composite process, these problems need to be solved through continuous research in materials science and process improvements.

Application fields of copper composite materials

Copper composite materials are widely used in many fields due to their excellent comprehensive properties.

1. Electronic and electrical industry: Copper has excellent electrical conductivity, so it is used in high-frequency circuit boards, connectors, conductive slip rings and other components in combination with other materials. It can improve the wear resistance and service life of the material while maintaining high electrical conductivity. For example, copper-graphite composites are often used in high-voltage switches, which can effectively reduce friction and extend the service life of the contactor.

2. Aerospace and automotive manufacturing: In these fields, the lightweight and high-strength requirements of materials are particularly important. Copper-aluminum composites are often used in the electrical systems of aircraft and automobiles because of their light weight and good electrical conductivity. In addition, the high temperature resistance and high strength of copper-ceramic composites make them widely used in high-temperature environments such as aircraft engines and gas turbines.

3. Mechanical engineering and industrial production: In the field of mechanical engineering, copper composites are used to make highly wear-resistant parts, such as bearings, sliding parts, etc. Copper-carbon composites are very common in such applications because the self-lubricating properties of carbon materials allow it to reduce wear and extend the life of equipment in high-speed equipment.

4. Energy and nuclear industry: In the field of nuclear energy, copper-ceramic composites are used in key components of nuclear reactors due to their high temperature stability and radiation resistance. In addition, copper composites are also used in the manufacture of energy equipment such as solar cells and fuel cells to improve energy conversion efficiency and equipment life.

Future development of copper composites

Copper composites undoubtedly have broad application prospects, especially in the context of the continuous development of emerging technologies, their demand will further increase. However, I think the development of copper composites still faces some challenges and limitations.

First, the complexity and cost issues of the manufacturing process require more research and improvement. Although copper composites have excellent performance, their manufacturing process often requires high-precision equipment and complex processes, resulting in high costs. This may not be economical for some large-scale application industries. Therefore, how to reduce production costs through technological innovation in the future is the key to the larger-scale application of copper composites.

Secondly, copper composites need more attention in terms of environmental protection. With the increase of environmental awareness, the recyclability of materials and their impact on the environment have become an issue that cannot be ignored. Although copper itself can be recycled, other materials added during the composite process (such as ceramics, carbon fiber, etc.) may not be easy to recycle. Therefore, the development of environmentally friendly copper composite materials and reducing the impact on the environment will also be an important direction in the future.

Finally, with the advancement of science and technology, the development trend of smart materials provides the possibility for further innovation of copper composite materials. For example, combining copper with smart materials (such as shape memory alloys or piezoelectric ceramics) to create composite materials with self-healing functions or intelligent responses will bring revolutionary breakthroughs in the future high-end manufacturing field.

As an advanced material, copper composite materials play an irreplaceable role in many fields due to their unique combination of properties. With the continuous advancement of manufacturing processes and in-depth research on new materials science, the application prospects of copper composite materials will be broader. Although there are still some technical and economic challenges, I believe that with the development of science and technology, these problems will eventually be solved. Copper composite materials will play a more important role in the future high-tech industry, promote the development of materials science and technology, and meet the growing industrial needs.