What is aluminum composite panel?

What is aluminum composite panel?

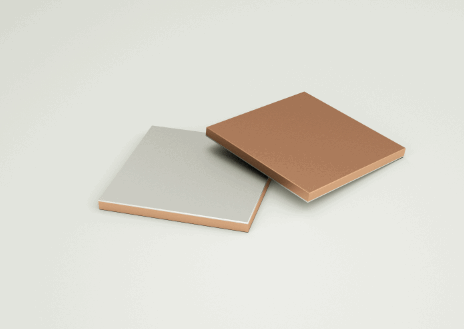

Aluminum composite panel, also known as aluminum-plastic composite panel, is a composite material composed of two layers of aluminum plates and an intermediate polyethylene (PE) or flame-retardant polyvinyl fluoride (PVDF) core material. It is widely used in architectural decoration, advertising signs, transportation, home decoration and other fields with its excellent properties such as light weight, firmness, corrosion resistance and beauty. Aluminum composite panel not only has the superior performance of aluminum, but also combines the flexibility and thermal insulation of polyethylene core material, making it an ideal choice among modern building materials.

Structure and production process of aluminum composite panel

Aluminum composite panel consists of three layers:

1. Panel: The surface aluminum plate of aluminum composite panel is usually made of high-quality aluminum alloy with a thickness of 0.15mm to 0.5mm. The surface of the aluminum plate is coated. Common coating types include fluorocarbon coating (PVDF) and polyester coating (PE), which have strong weather resistance and UV resistance, and can maintain surface brightness and color stability for a long time.

2. Core material: The middle layer of aluminum composite panel is polyethylene (PE) or flame retardant material. The polyethylene core material is lightweight and has a certain elasticity, which can effectively reduce the load on the building. For construction projects with high fire protection requirements, mineral-filled core materials with fire-resistant properties can also be selected to improve safety.

3. Back panel: The back aluminum plate is similar to the panel, usually made of aluminum alloy, and its main function is to provide structural support and impact resistance.

The production process of aluminum composite panels mainly includes hot pressing, cold pressing and coating processes. During production, the aluminum plate and the core material are compounded together by high temperature and high pressure to ensure the close combination between the aluminum plate and the core material. After the surface of the aluminum plate is coated, its corrosion resistance and weather resistance are further enhanced.

Superior performance of aluminum composite panels

The reason why aluminum composite panels can be widely used in many fields is due to their excellent performance in many aspects:

1. Lightweight and high strength

The weight of aluminum composite panels is lighter than traditional aluminum or steel plates, but their strength is not inferior. This makes it an ideal material for exterior wall decoration and billboard production. Compared with traditional stone and glass, aluminum composite panels are more convenient to install and can effectively reduce the load of building structures.

2. Strong corrosion resistance and weather resistance

The surface coating of aluminum composite panels has excellent antioxidant properties and can resist acid rain, air pollution and ultraviolet erosion. In particular, aluminum composite panels with PVDF coating have outstanding weather resistance and are suitable for building exterior walls or signboards that are exposed to the outside for a long time.

3. Beautiful appearance

The surface of aluminum composite panels can achieve a variety of colors and textures through spraying, rolling and other processes. Whether it is metal texture, wood grain, stone grain, or bright pure color, aluminum composite panels can provide a wealth of choices to meet the needs of different architectural styles.

4. Easy processing

Aluminum composite panels have good plasticity and can be cut, bent, stamped and processed into various complex shapes. Whether it is used for curved building facades or customized designs for signboards, aluminum composite panels can easily achieve it.

5. Good heat and sound insulation performance

The polyethylene core material in the aluminum composite panel not only plays a lightweight supporting role, but also has a certain heat and sound insulation effect, which can effectively reduce the energy consumption of buildings and improve the comfort of living and working environments.

Application fields of aluminum composite panels

Due to its diverse performance and appearance options, aluminum composite panels are widely used in different fields:

1. Building decoration

Aluminum composite panels are very common in building exterior wall decoration, especially curtain walls of high-rise buildings. Its light weight and high strength make installation convenient and provide excellent wind pressure resistance. In the interior wall decoration of buildings, aluminum composite panels can also be used in partitions, ceilings and other locations to provide rich decorative effects.

2. Advertising signs

Aluminum composite panels are one of the preferred materials for making billboards and signs. Its light weight and flatness make it widely used in large-format billboards. At the same time, it has strong weather resistance and can be used outdoors for a long time without fading.

3. Transportation Manufacturing

The lightweight and strength advantages of aluminum composite panels also make them used in the manufacturing of some transportation vehicles, such as train carriages, subway stations and other structural parts. Its fireproof and soundproof properties also provide better safety and comfort for passengers.

4. Home Decoration

In interior decoration, aluminum composite panels can be used to make cabinets, door panels, furniture panels, etc. Its diverse color and texture options can meet the personalized needs of modern home design.

Future Development Prospects of Aluminum Composite Panels

With the growing demand for green, environmentally friendly and lightweight materials in the construction industry, aluminum composite panels, as a material that combines functionality and decoration, have broad future development prospects. Here are some of my views on the future trends of aluminum composite panels:

1. Increasing demand for environmentally friendly aluminum composite panels

Modern buildings pay more and more attention to environmental protection and sustainable development. More environmentally friendly materials, such as recyclable aluminum and bio-based core materials, can be introduced into the production of aluminum composite panels. In addition, coating technology that reduces VOC emissions will gradually become popular, improving the environmental friendliness of materials.

2. Improvement of fire resistance

With the improvement of fire protection standards, especially in high-rise buildings and public facilities, the requirements for the fire resistance of materials are becoming more and more stringent. In the future, aluminum composite panels will further improve the fire resistance of their core materials and adopt more inorganic fireproof materials to ensure safety under high temperature conditions.

3. Personalized customization trend

With the diversification of design styles and the increase in customer demand for personalization, aluminum composite panels will provide more customized options in color, texture, and shape. Through digital printing technology, more complex patterns and designs can be achieved on the surface of aluminum composite panels to meet the needs of different buildings and decorations.

As a lightweight, beautiful, and versatile composite material, aluminum composite panels are widely used in modern architectural decoration and other fields. Its superior performance makes it an excellent choice to replace traditional materials, especially in energy saving and environmental protection, processing convenience and weather resistance.

In the future, with the development of science and technology and changes in market demand, improvements in aluminum composite panels in fire protection, environmental protection, personalization, etc. will further enhance their market competitiveness. In my opinion, aluminum composite panels are not only a popular material in the current field of architectural decoration, but will continue to occupy an important position in the future.

The above is a detailed introduction to what aluminum composite panels are. Apex-New Material specializes in the production of aluminum composite panels. We can recommend and customize aluminum composite panels of different specifications and sizes according to industry characteristics. If you have any needs, please contact us: postmaster@apex-newmaterial.com