Which alloys can be effective solder materials?

Which alloys can be effective solder materials?

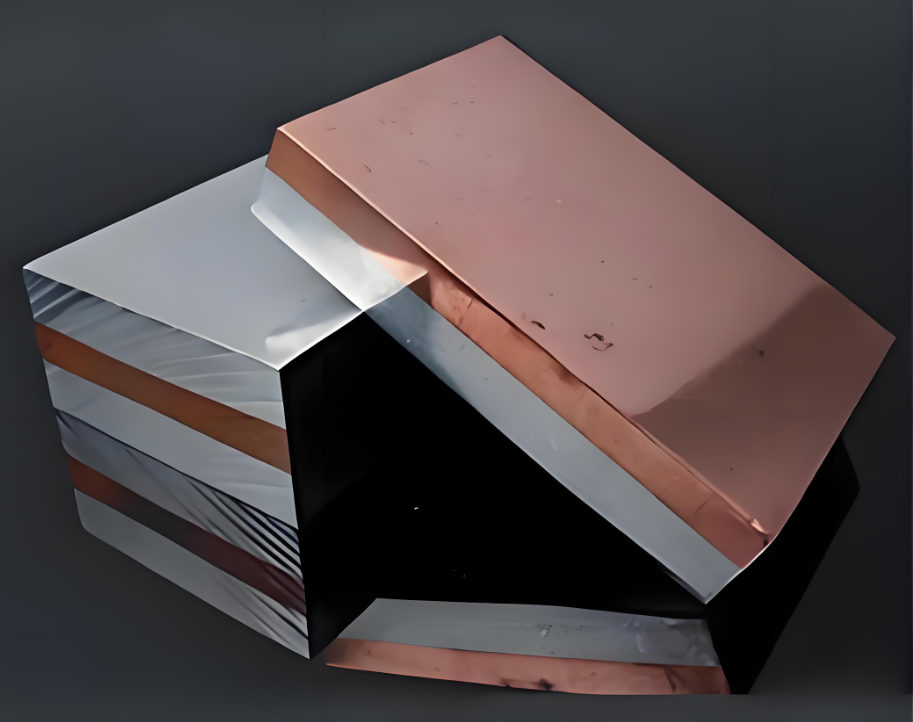

In modern welding technology, choosing the right solder material is crucial to ensure welding quality and reliability. Alloy solders are widely used in electronics, automobiles, aerospace and other fields. Apex-New Material Alloy Solder Customization will explore several common solder alloys, analyze their characteristics and applicable scenarios, in order to provide valuable reference for the selection of welding processes.

Selection of solder materials

Solder is a metal material used to fill the joints during welding. Its main function is to form a strong connection point by melting and solidifying. The selection of solder alloys needs to consider many factors, such as melting point, fluidity, mechanical properties, chemical stability and environmental friendliness.

Common solder alloys and their characteristics

1. Tin-lead alloy (Sn-Pb alloy)

Composition and characteristics:

Main components: tin (Sn) and lead (Pb), usually 60% tin and 40% lead.

Melting point: 183°C.

Advantages: good fluidity and wettability, easy to operate, suitable for welding of electronic components.

Disadvantages: The toxicity of lead is harmful to the environment and health, and many countries have restricted or banned the use of lead alloy solder.

Application scenarios:

Mainly used for welding of electronic products, such as solder joints on circuit boards (PCBs).

2. Lead-free tin alloy (Sn-Ag-Cu alloy)

Composition and characteristics:

Main components: tin (Sn), silver (Ag) and copper (Cu), with a common ratio of 96.5% tin, 3% silver and 0.5% copper.

Melting point: 217-221°C.

Advantages: It has a higher melting point and mechanical strength than tin-lead alloy, meets environmental protection requirements, is lead-free and environmentally friendly.

Disadvantages: It has slightly worse fluidity than tin-lead alloy, is more difficult to weld and has a higher cost.

Application scenarios:

It is widely used in the welding of electronic products and automotive electronic equipment that require environmental protection.

3. Aluminum solder alloy

Composition and characteristics:

Main components: aluminum and its alloys, such as aluminum-magnesium alloy and aluminum-silicon alloy.

Melting point: about 600-700°C (the melting point of aluminum is 660°C).

Advantages: suitable for aluminum welding, can provide good corrosion resistance and strength.

Disadvantages: aluminum welding technology requirements are high, easy to form oxide film during welding, affecting welding quality.

Application scenarios:

Widely used in the automotive industry, aerospace and aluminum structural parts welding.

4. Silver solder alloy

Composition and characteristics:

Main components: silver (Ag) and copper (Cu), such as silver-copper alloy (Ag-Cu alloy).

Melting point: about 780-830°C.

Advantages: excellent conductivity and corrosion resistance, suitable for high-precision and high-performance welding requirements.

Disadvantages: high cost, the price of silver solder is usually more expensive than other solders.

Application scenarios:

Mainly used for jewelry making, high-end electronic components and high-temperature and high-strength welding.

Selection criteria for solder materials

When selecting suitable solder materials, the following aspects should be considered:

1. Melting point and operating temperature:

The melting point of the solder must be suitable for the temperature requirements of the welding material to ensure a smooth welding process.

2. Mechanical properties:

The solder must have sufficient strength and toughness to ensure the reliability of the welded joint.

3. Chemical stability:

Choosing solder with good chemical stability can reduce corrosion and oxidation after welding and extend the service life.

4. Environmental requirements:

With the strict environmental regulations, lead-free solder has become the mainstream choice and meets the requirements of environmental protection.

5. Cost:

Choose the appropriate solder material according to the budget to balance performance and cost.

When selecting solder materials, comprehensive consideration should be given to specific application requirements and environmental requirements. Tin-lead alloys were once widely used due to their excellent welding performance, but were gradually replaced by lead-free tin alloys due to environmental issues. Aluminum solder and silver solder play an important role in specific applications. Understanding the characteristics and application scenarios of each solder can help us make more scientific and reasonable choices in actual operations, thereby ensuring the welding quality and long-term stability of the equipment.