Performance characteristics of silicon aluminum alloy

Performance characteristics of silicon aluminum alloy

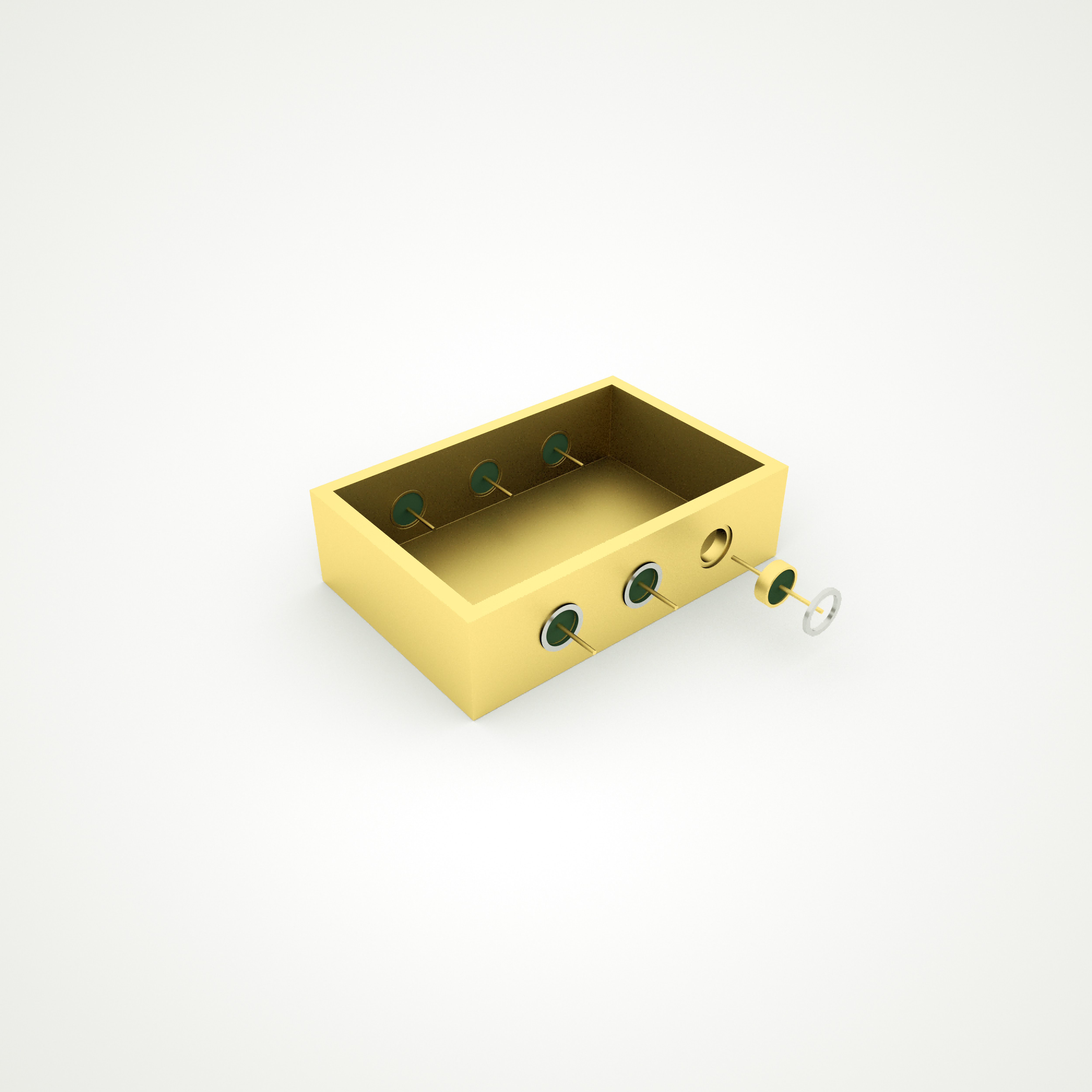

1. Composition and production method of silicon aluminum alloy

Silicon aluminum alloy is an alloy material made of aluminum and silicon as the main raw materials, adding a certain amount of carbon, hydrogen, nitrogen, etc., through smelting and casting processes. There are two main production methods of silicon aluminum alloy: smelting method and electrolysis method. Among them, the smelting method is to put the raw materials into a high-temperature furnace for smelting, and obtain the alloy through crystal growth technology; the electrolysis method is to electrolyze the raw materials in an electrolytic cell to obtain a silicon aluminum alloy with higher purity.

2. Performance characteristics of silicon aluminum alloy

1. Good corrosion resistance

The main components of silicon aluminum alloy are aluminum and silicon, of which the silicon content can reach more than 30%. Silicon has very good oxidation resistance, and after oxidation, it can form an oxide layer to protect the surface of aluminum, thereby playing a good role in corrosion resistance. Therefore, silicon aluminum alloy can have good corrosion resistance in a variety of harsh environments such as high temperature and high pressure.

2. Excellent high temperature stability

Silicon aluminum alloy has high room temperature strength and good high temperature stability. This is because silicon and aluminum can form a stable compound Al8Si3 at a certain temperature, thus maintaining good mechanical properties and stability under high temperature conditions.

3. Good plasticity and forgeability

Silicon aluminum alloy has good plasticity and forgeability, and can be processed by thin plate processing, cold drawing, rolling and other processing technologies. In addition, silicon aluminum alloy can also be heat treated under certain conditions to change its organizational structure and mechanical properties, so as to meet the use needs of different fields.

III. Application fields

Silicon aluminum alloy is widely used in the industrial field. Silicon aluminum alloy with good corrosion resistance, high temperature stability and plastic forgeability is widely used in aerospace, automobile manufacturing, electronics, electrical appliances, construction and other fields. Especially in the field of aviation and aerospace, silicon aluminum alloy is widely used in the manufacture of engine, airfoil, shell and other parts.

Silicon aluminum alloy is an important aluminum alloy material with excellent corrosion resistance, high temperature stability and plastic forgeability. It is widely used in aviation, aerospace, automobile manufacturing, electrical appliances, construction and other fields. With the continuous emergence of new materials and new processes, the performance of silicon aluminum alloy will continue to improve, bringing more opportunities and possibilities for applications in various fields.

Chengdu Apex-New Material was established in December 2016, mainly focusing on the research and development, production and sales of cutting-edge alloy materials.

In 2017, the company introduced foreign alloy brazing material production equipment and formed a professional R&D team. In the same year, it established a brazing material R&D center and a silicon-aluminum alloy R&D center. At present, it has reached the international advanced level in high-cleanliness gold-based alloy solders (Au80Sn20, Au88Ge12, Au96.85Si3.15), other alloy brazing materials (Ag72Cu28, SAC305, Sn63Pb37, In97Ag3, Bi58Sn42 and other alloy brazing materials), pre-set gold-tin cover plates, silicon-aluminum alloys (AlSi27, AlSi50, AlSi70, Al4047), etc., and is committed to providing customers with more professional, efficient and reliable process solutions.